Reduce the footprint, contamination, unmanageable wiring and tubing nests, and overall inventory costs and production time by using manifolds.

We offer compact, preassembled, precise microfluidic manifolds in a wide variety of materials that integrate seamlessly with our fluid transfer components.

Using our proprietary bonding processes, in-house CNC machining, and precision metrology equipment, we ensure consistent and precise fluid transport in your custom, milled manifolds.

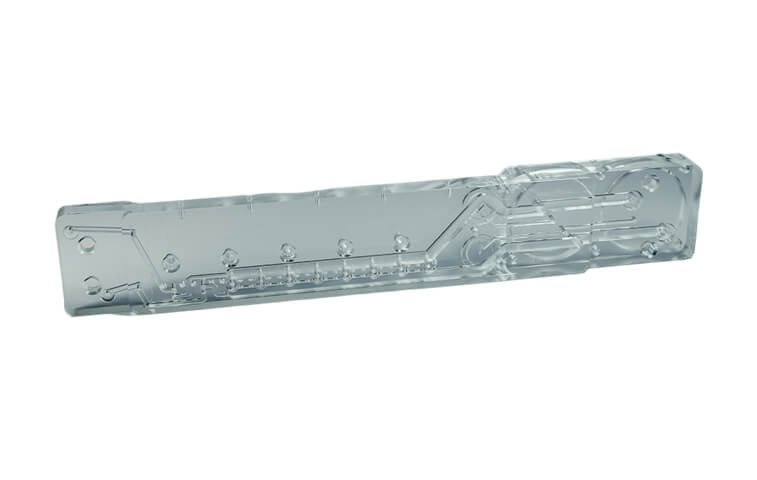

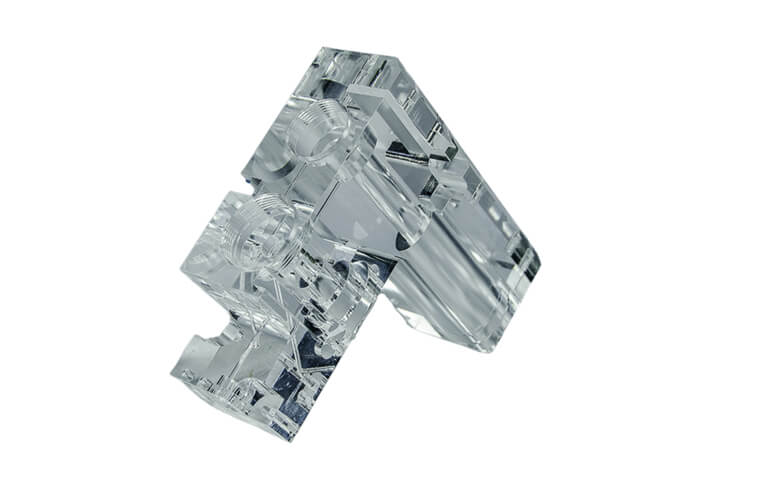

Our optimized diffusion bonding methods allow for the cost-effective creation of single or multilayer manifolds free of contamination. This pure method of fusing without adhesives or solvents results in smooth fluid paths with channel and hole sizes as small as 0.004”. Diffusion-bonded manifolds are ideal for creating complex fluid paths and are available in translucent materials including acrylic and Ultem.

Download Manifold Brochure

Our customers enjoy the confidence of repeatable and precise single-piece, machined manifolds without feature drift. In addition to our micromachining, milling, and turning capabilities, our advanced machine shop uses high-speed CNC machines calibrated to repeatedly hold tolerances of 0.0002”, or 5 percent of the width of a human hair. Machined manifolds are ideal for simple, single-layer designs and are available in a wide variety of materials including acrylic, Ultem, polycarbonate, polysulfone, PPSU, PEEK, Delrin, and more.

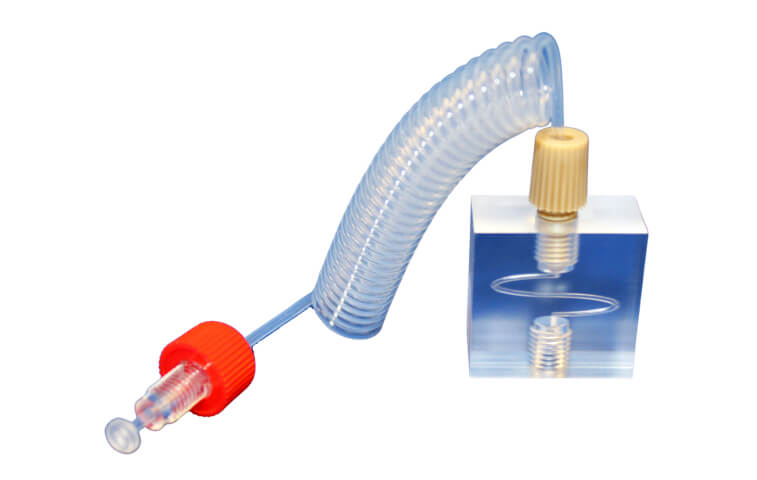

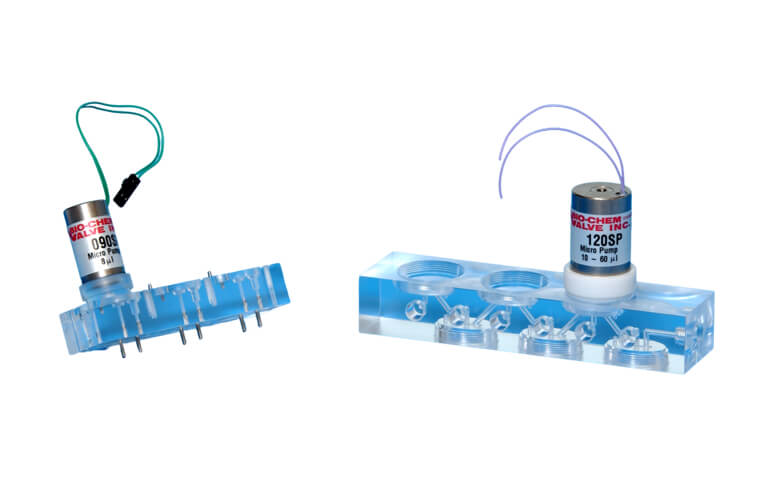

Integrating manifolds with our other fluid components into subassemblies streamlines your supply chain management and reduces inventory complexity.

Combining manifold designs with your other fluid components ensures instrument reliability and precision through our compatible component platform. We can integrate valves, fittings, tubing, sensors, and pumps to reduce the complexity of engineering, sourcing, documenting, and maintaining multiple disparate fluid components. This integration process is optimized and tested for your most critical, high volume assemblies.

Accelerate your instrument production through our in-house testing services. Gross-leak testing ensures your assembly arrives ready to integrate into your machine, worry-free. Additional performance testing is available to save you time and headaches.

In addition to your choice of materials, we offer a wide variety of manifold configurations for increased precision, improved chemical compatibility, reduced carryover, and increased strength.

Polished manifolds allow for enhanced visibility of fluid paths while smoothing out any tooling marks remaining from machining processes. Our customers have the option of vapor polishing or flame polishing to produce a professional aesthetic while improving the surface finish of the manifold. Our combination of proprietary machining and polishing capabilities complement your applications by producing optically clear surfaces as low as 1 - 2 Ra.

Ultrasonic inserts provide increased strength to manifolds that incorporate threaded components for repeated installations. In brittle materials, such as acrylic, our engineering team instinctively integrates ultrasonic inserts to ensure your manifold supports the life of the instrument.

Danbury, CT (Diba)

Boonton, NJ (Bio-Chem)

Shanghai, CN (HCG)

+86.21.6151.9061

Access best-in-class thought leadership on a wide range of topics around fluidics, diagnostic instrumentation, device manufacturing, and more.

© 2021 Arcmed