Control and direct fluids within an instrument system with guaranteed precision and reliability.

Experience precise and reliable fluid control within an instrument system with industry-leading pumps and valves.

Choose from a variety of piston, peristaltic, and solenoid-operated pumps for high precision and accurate dispensing of reagents, wash fluids, and samples.

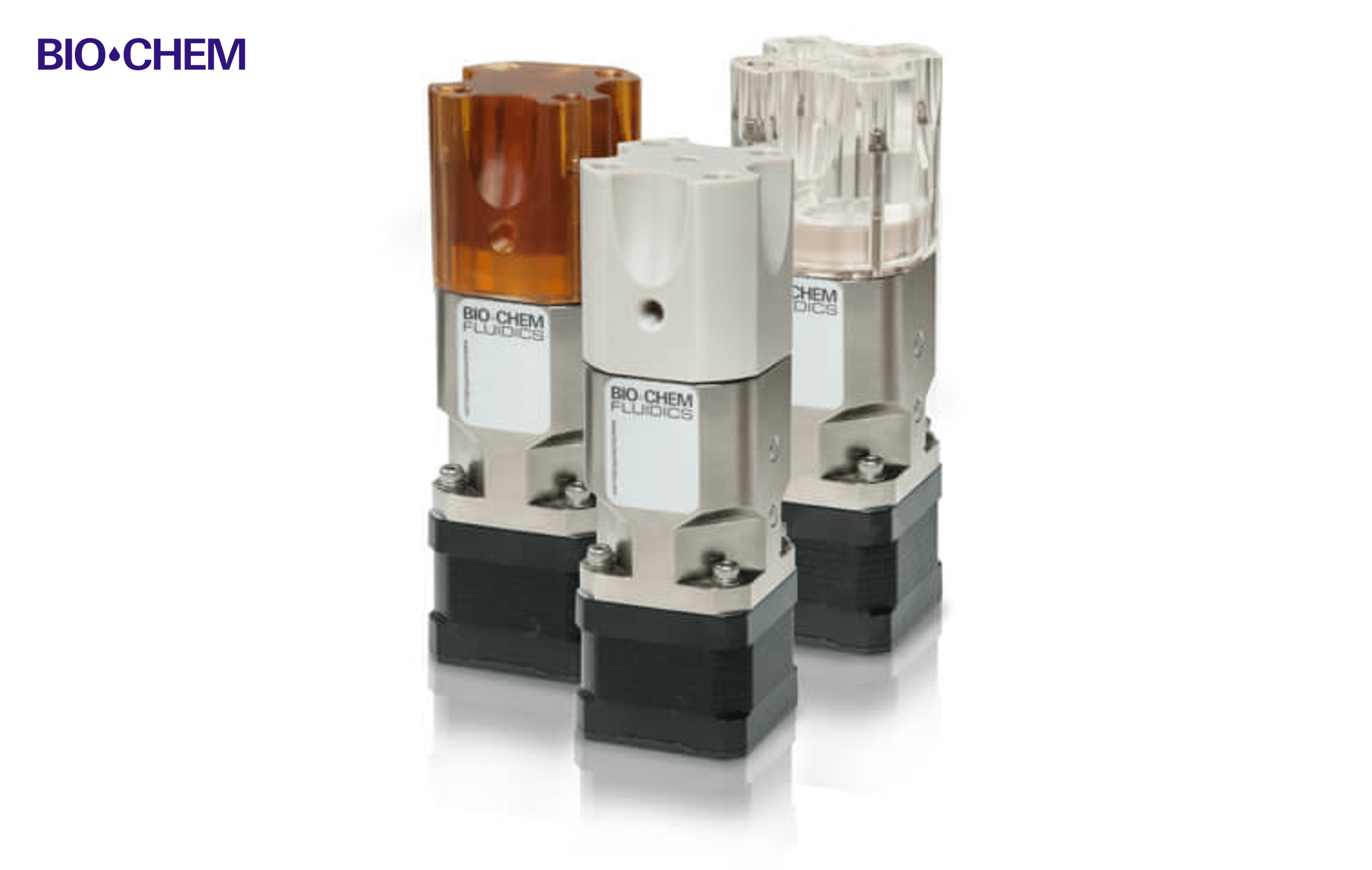

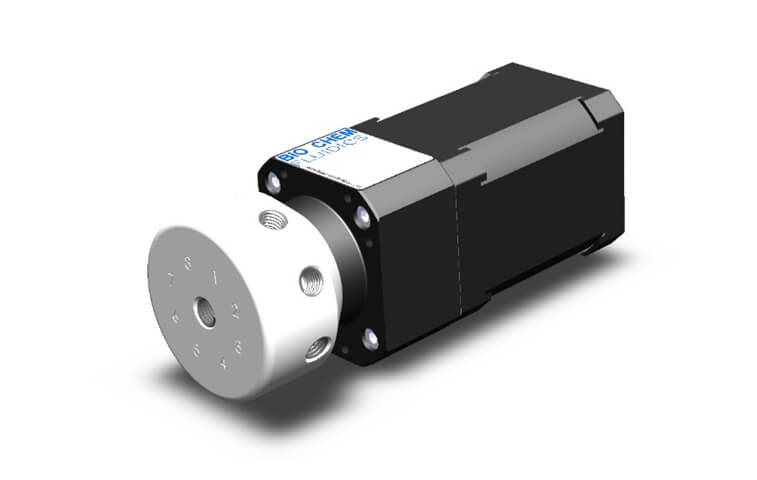

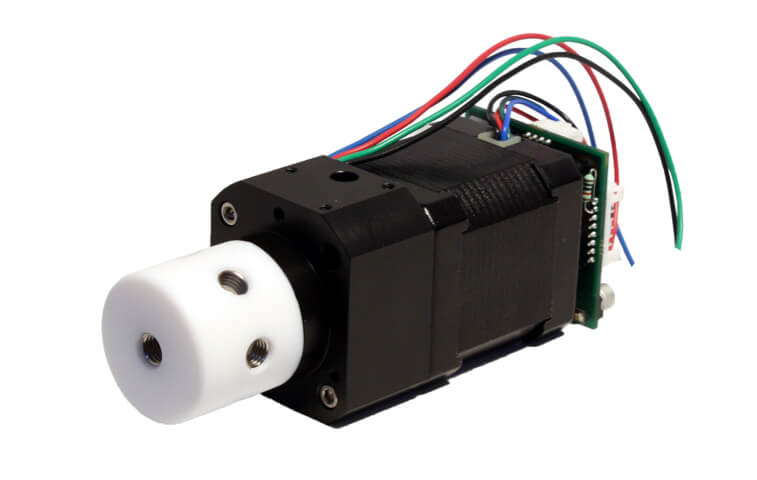

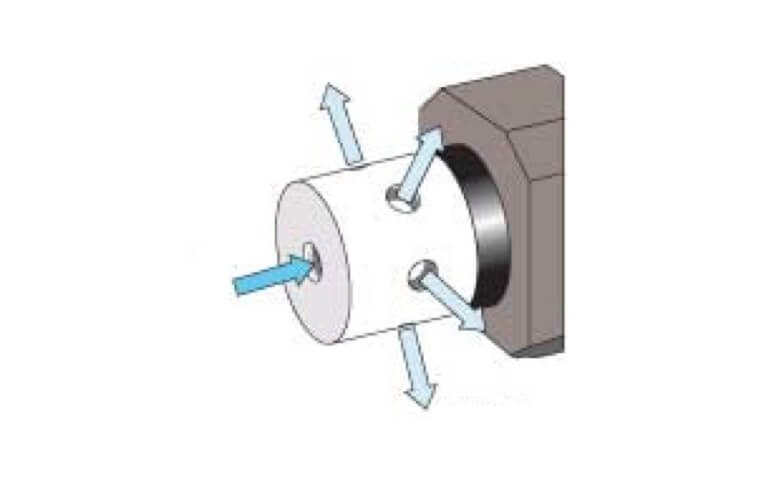

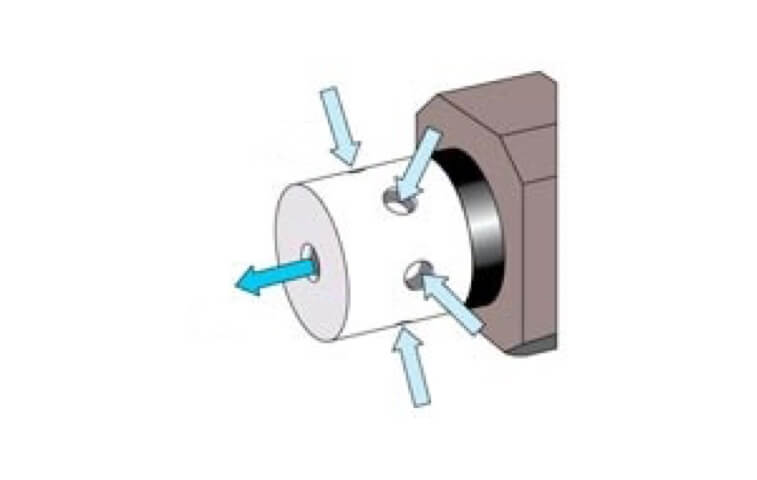

Piston pumps are reciprocating-type, positive displacement pumps that move fluid by trapping a fixed amount and forcing it through the discharge port. These pumps are the longest lasting and have the widest variety of configurations and material choices on the market.

Full customization also available, contact us today!

*Accuracy and precision depend on several variables including, but not limited to, pump speeds, accelerations, run current, microstepping, and fluid characteristics.

Download Piston Pump Brochure

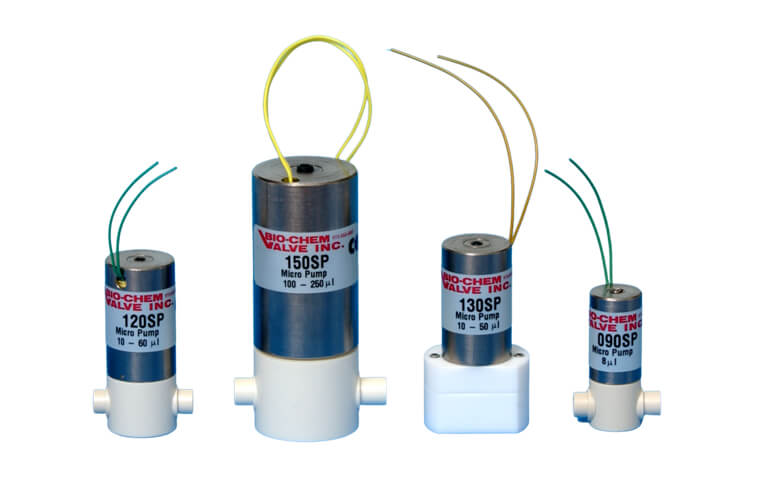

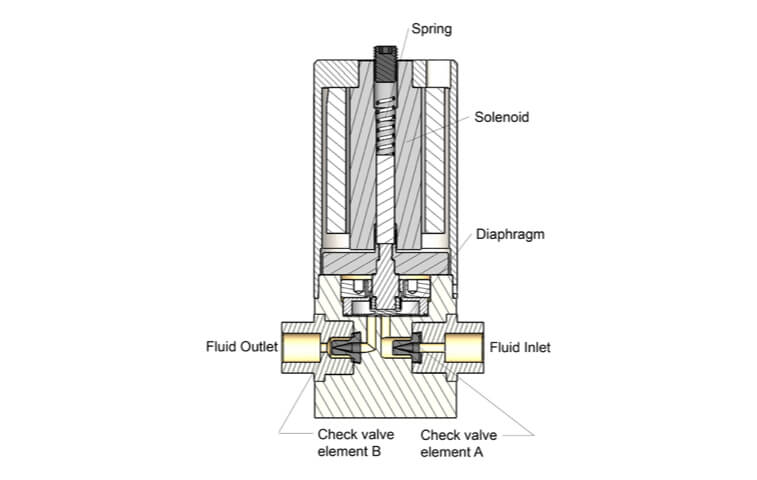

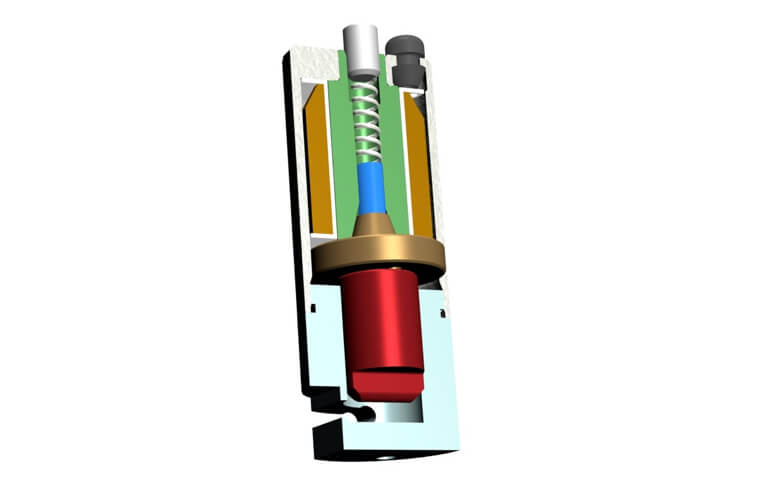

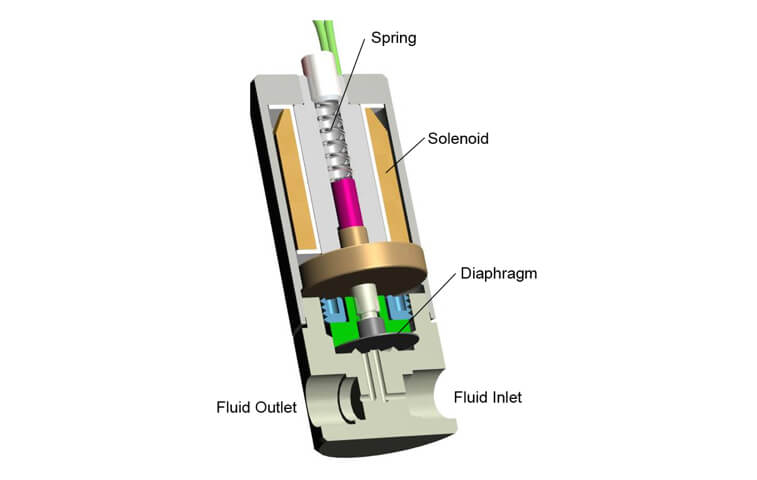

Solenoid-operated micro pumps are designed to provide precise, repeatable, and discrete dispensing of fluid in which the flow path is isolated from the operating mechanism by a flexible diaphragm to ensure low carryover. Our self-priming micro pumps are available in a range of different sizes and materials to adapt to highly aggressive or high-purity applications.

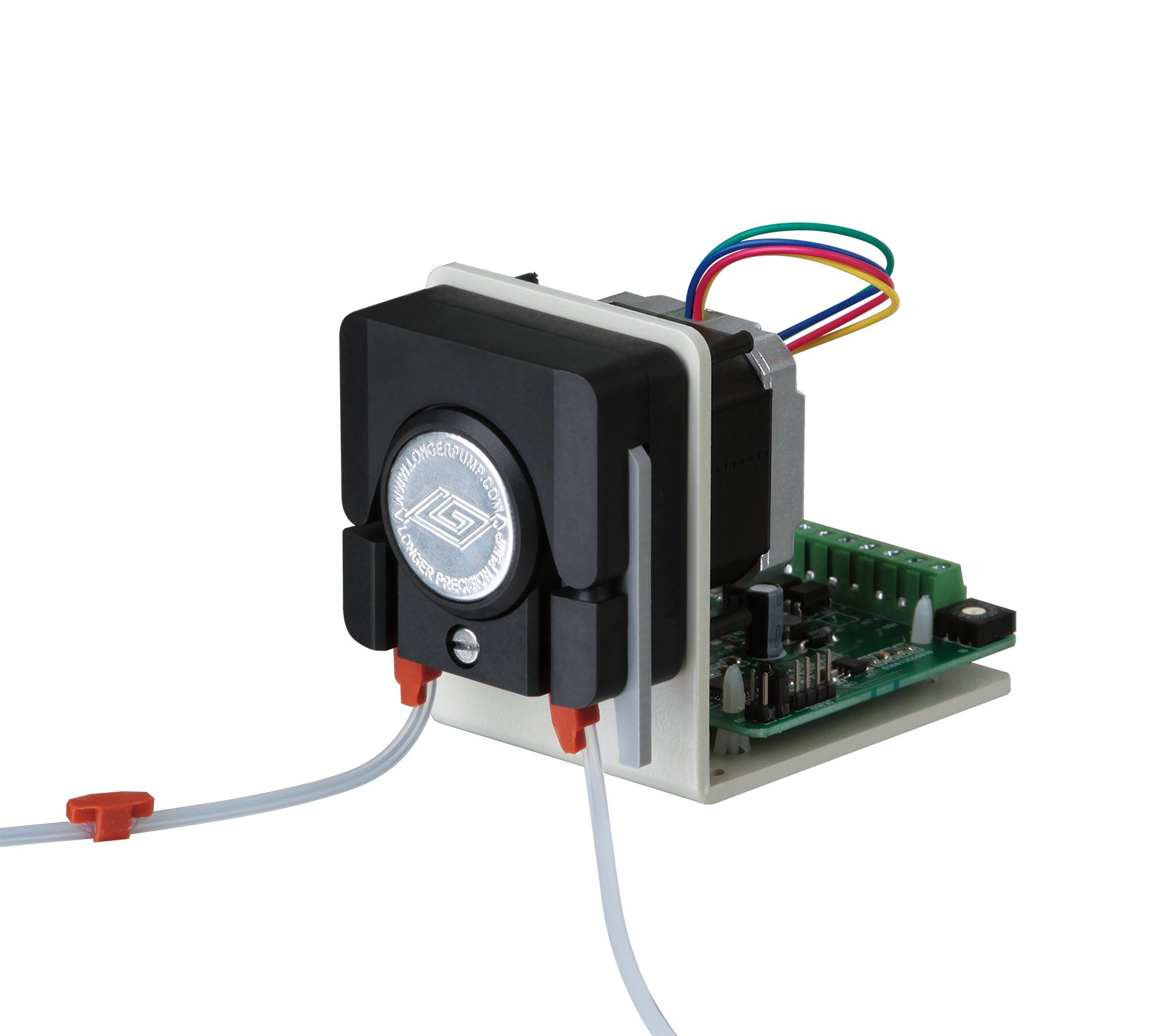

Peristaltic Pumps operate by squeezing and releasing a flexible tube, offering a contamination-free and precise fluid transfer solution for a wide range of liquids (including shear-sensitive biological materials). Arcmed has Peristaltic Pumps for customers in the OEM medical, pharmaceutical and environmental applications.

Arcmed is aligned with its group sister-company to provide Peristaltic Pump and Tubing solutions for OEM applications.

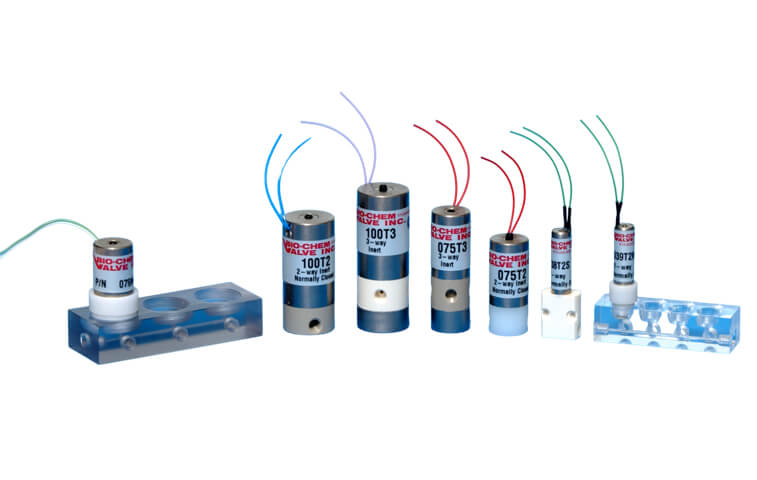

Select from a variety of pinch, isolation, flow selection, rocker, and electronic rotary-style valves to open or close off fluid pathways.

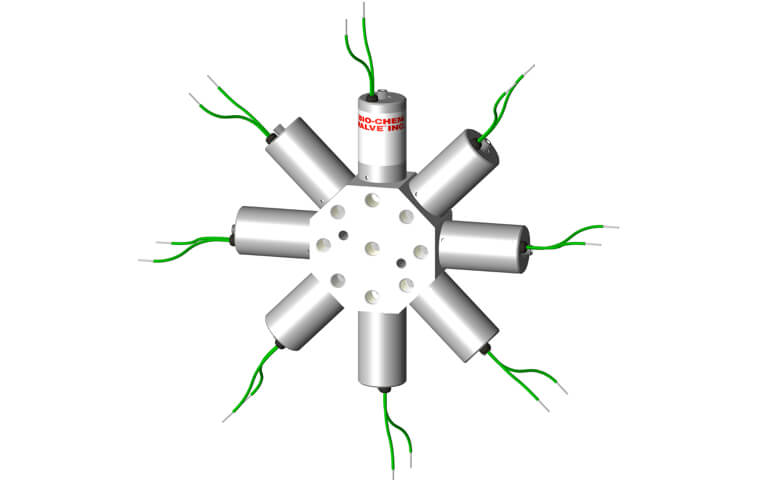

Pinch valves feature a contoured, smooth design for simple tube installation and removal that's easily integrated and mounted onto manifolds. These valves are available in multiple configurations to control flow across two, three, or even eight medical-grade tubing lines to provide an inert flow path with zero dead volume.

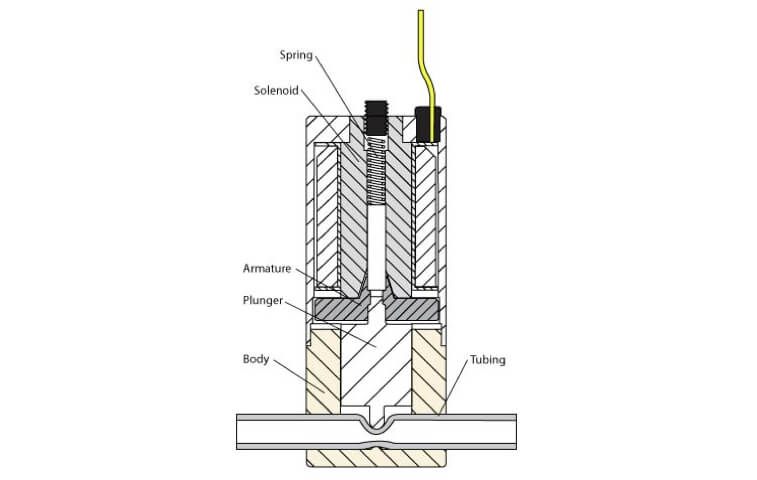

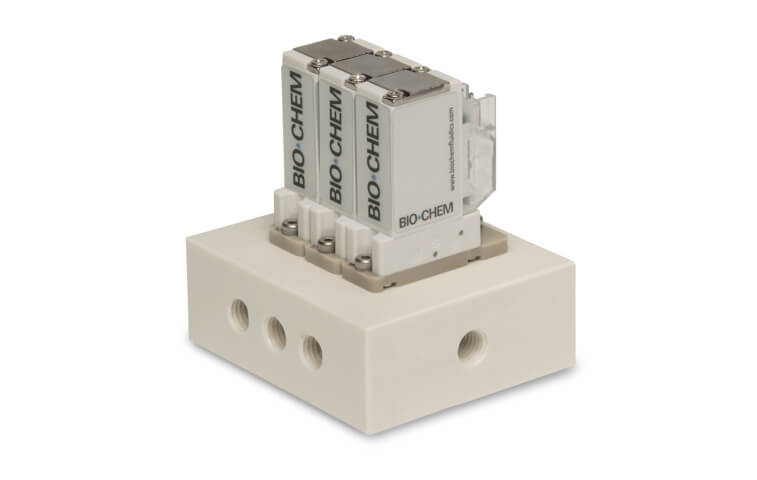

Solenoid-operated isolation valves offer instrument designers a completely inert, nonmetallic fluid path, using a flexible diaphragm to isolate the solenoid actuation mechanism from the fluid path. Isolation valves deliver low internal volumes, precise flow control, and excellent ease of installation.

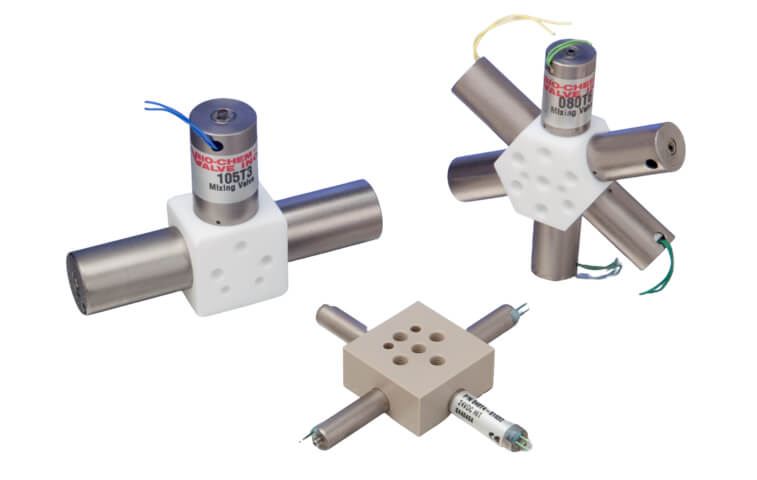

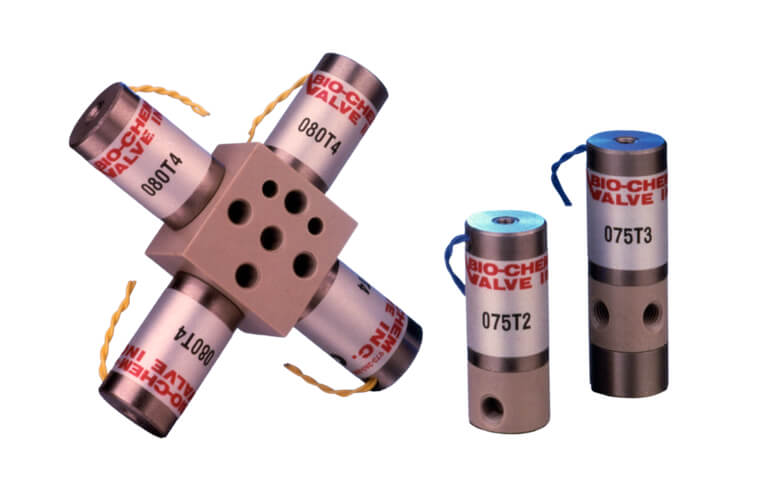

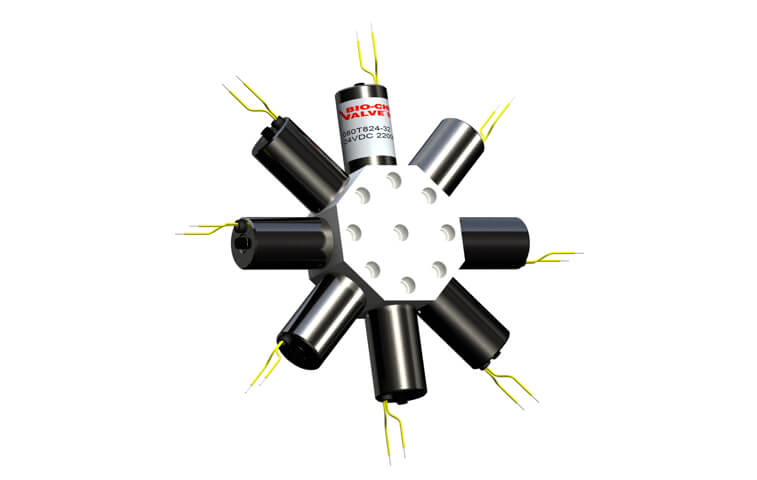

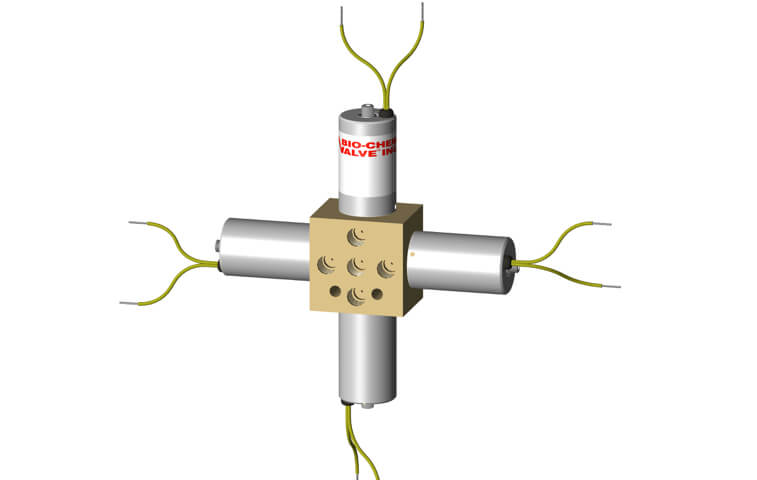

Flow selection valves combine multiple valve actuators into a single, compact unit to provide flow paths of equal length. Flow paths can be made from extremely inert materials, making these valves particularly suitable for highly aggressive or high-purity fluid applications.

Our Opus rocker valves offer a stable, higher-flowing, long-lasting valve solution, ultimately setting a new standard in modern fluidics for dependable fluid handling in a small space and a precise flow rate with a small footprint and low internal fluid volume. Rocker valves are ideal in applications that require fluid interaction with optical detectors and increased flow rates without an increased footprint.

Electric rotary valves, or rotary shear valves, are stepper, motor-driven fluid handling valves that provide an inert flow path for aggressive fluids by aligning holes in a PCTFE rotor with holes in the PTFE body. ERVs can be used for port selection or loop injection applications.

Danbury, CT (Diba)

Boonton, NJ (Bio-Chem)

Shanghai, CN (HCG)

+86.21.6151.9061

Access best-in-class thought leadership on a wide range of topics around fluidics, diagnostic instrumentation, device manufacturing, and more.

© 2021 Arcmed