Standard and custom tubing assemblies with a variety of options

You can use tubing as the conduit to transfer fluid throughout your instrument. We offer a wide variety of tubing assemblies and sample loops and mixing coils with labeling and printing, kitting, and thermoforming options.

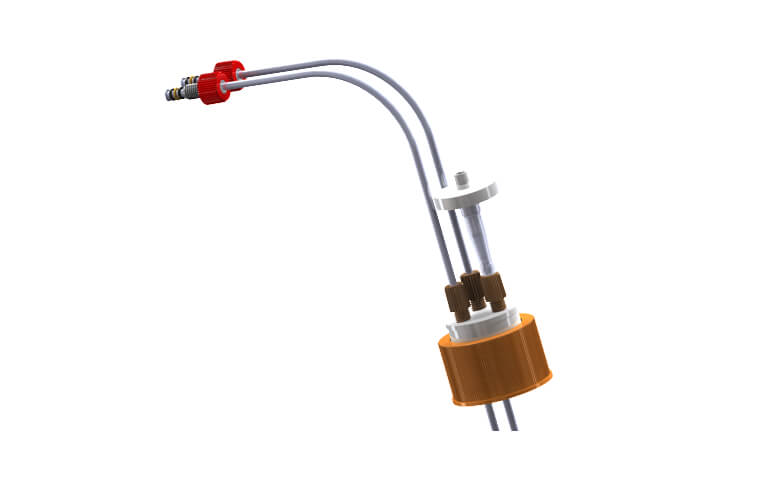

Arcmed manufacturers more than 5,000 unique tubing assemblies annually with each designed to our customers’ exact specifications. Custom tubing applications typically fall into two distinct categories: 1. sampling and 2. washing and waste. For the sampling side of an instrument, we recommend precision, chemically inert tubing assemblies designed to avoid dead volume and reduce carryover. For the washing and waste side of an instrument, we recommend soft tubing assemblies to quickly and easily remove unneeded fluid from the system.

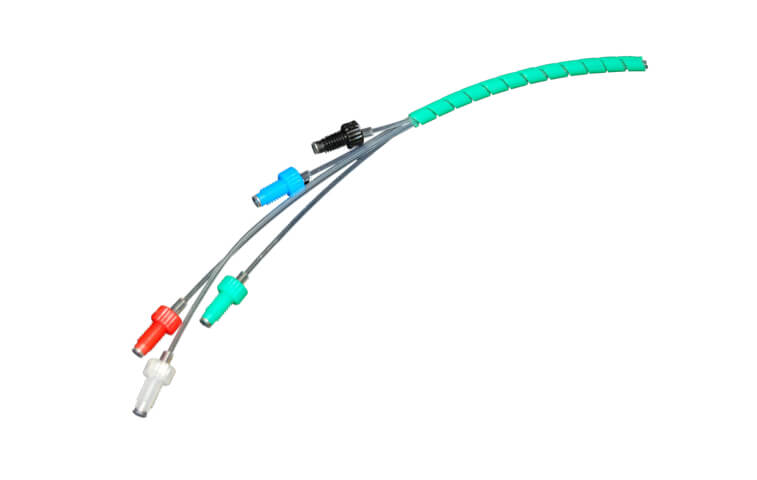

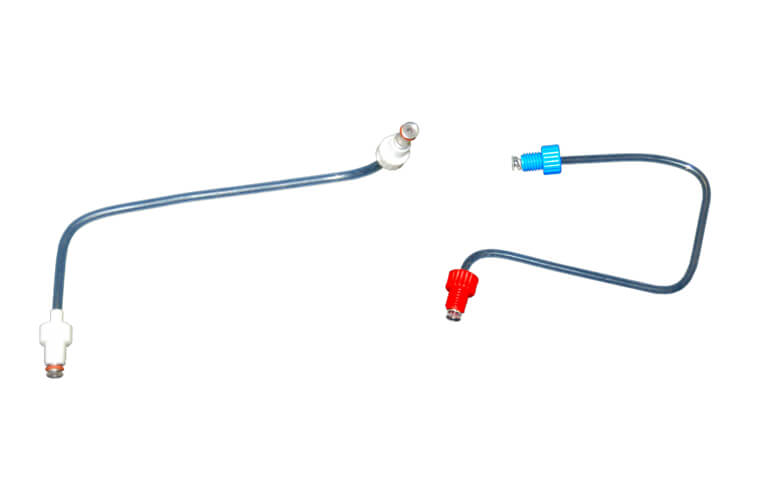

Tubing assemblies can be printed and labeled using a variety of methods to ensure straightforward installation and servicing. Color-coded fittings, sleeving, heat shrink labels, wraparound labels, and clip-on labels are all available to help operators identify the correct connection points within your instrument. While heat shrink labels are typically the easiest and most economic approach to label hard polymer tubing, more permanent methods are also available for harsh and unique environments.

We can print text onto semirigid plastic tubing, such as PTFE, FEP, and LDPE, using our laser etching capabilities, and can print text onto soft plastic tubing, such as PVC, Tygon, and silicone using our inkjet machines.

Request a Quote

Kitting simplifies your supply chain efforts by reducing a large list of disparate parts into a single part number specific to your application. By efficiently packaging your components together, we ensure your set of tubing assemblies easily integrates into your manufacturing and servicing processes to speed your build cycle and field service times.

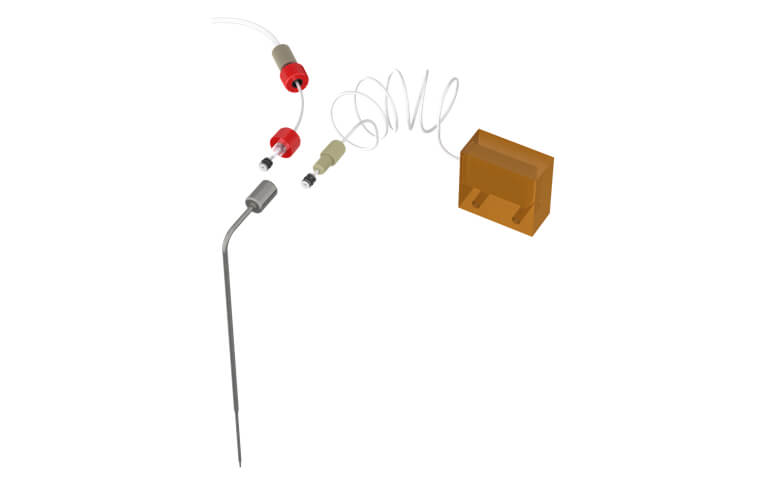

Tight spaces in many diagnostic and analytical instruments make it difficult to maintain consistent fluid paths in standard tubing. Thermoformed tubing assemblies can be custom designed with 2D or 3D dimensional precision bends and coils that fit neatly into instruments. Our expert engineer and manufacturing teams create thermoformed tubing designs to prevent kinking and improper installation. Available tubing materials include FEP, PTFE, PFA, ETFE, PVC, LDPE, PVDF, TPU, and PEEK.

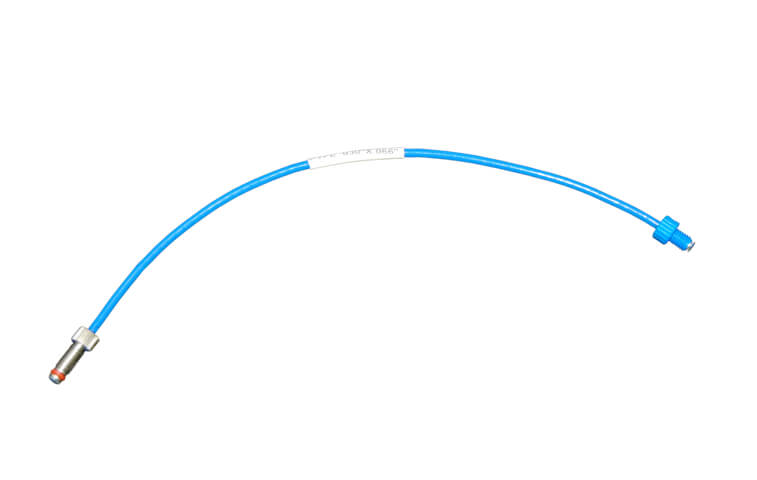

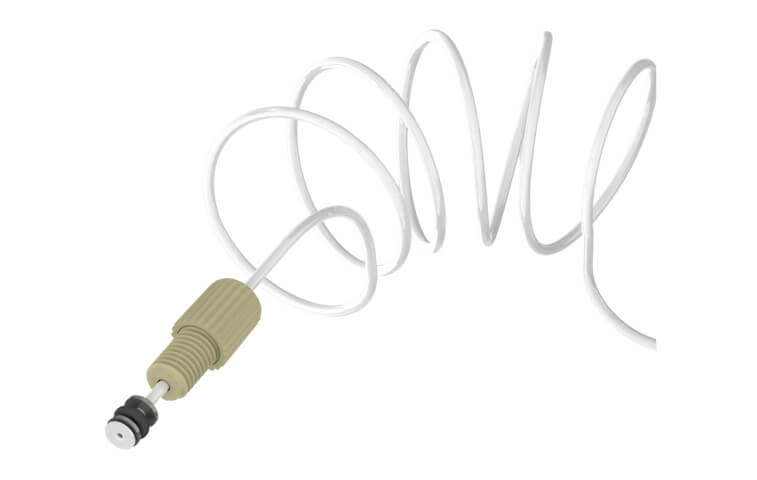

Download Connection CatalogStandard tubing assemblies are ideal during your instrument design phase to accelerate breadboarding and prototyping. These high-quality, in-stock assemblies feature our proprietary Flare Connection System and Click-N-Seal fittings to minimize dead volume and create a reliable, secure connection. A variety of sizes, materials, and connector options are available to reduce the time and cost typically associated with custom tubing assemblies.

Standard tubing assemblies are available in a variety of materials and sizes:

Standard tubing assemblies are available with a variety of our proprietary fitting and tubing designs.

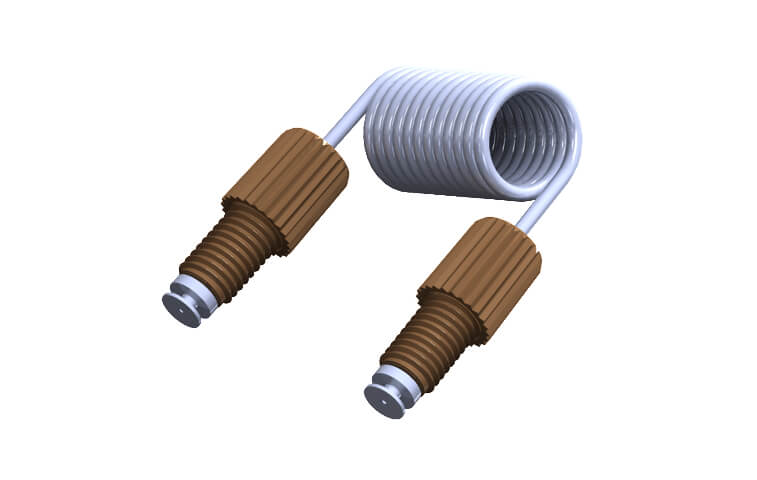

Sample loops and mixing coils are designed with Click-N-Seal Ultra fittings and Flared tubing for a secure and inert connection. Standard loops and coils are available in a variety of sizes, while designs compatible with alternative connection systems are available on request.

Sample loops allow for repeatable injection or sampling within your instrument and are available in a variety of sizes.

Mixing coils allow for repeatable integration of fluids within your instrument and are available in a variety of lengths.

Danbury, CT (Diba)

Boonton, NJ (Bio-Chem)

Shanghai, CN (HCG)

+86.21.6151.9061

Access best-in-class thought leadership on a wide range of topics around fluidics, diagnostic instrumentation, device manufacturing, and more.

© 2021 Arcmed